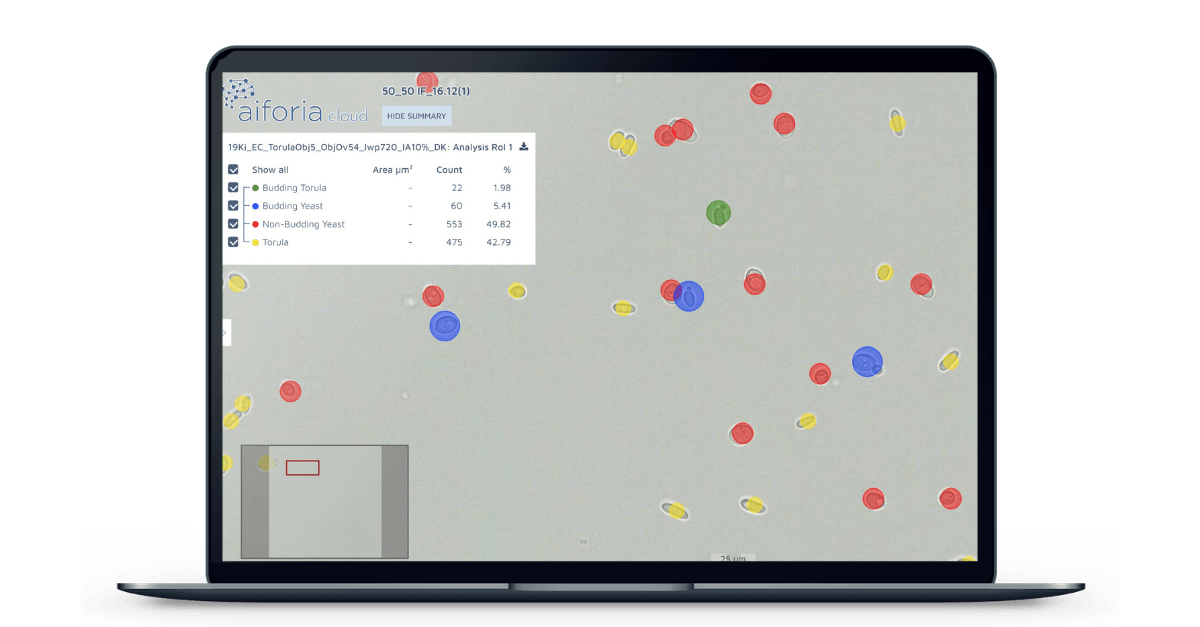

Yeasts are common microorganisms used in industrial fermentation processes such as food and alcohol production. Microbial contamination of such processes is inevitable, as most of the fermentation substrates are not sterile. Contamination can cause a reduction of the final product concentration and render industrial yeast strains unable to be reused. Hence, contamination detection is critical to maximizing production efficiency and the quality of products. Often, this process involves plating assays, although results may take days to obtain, after which manual analysis of the plates is also tedious. Lallemand Inc., a yeast production company, is speeding up the process using Aiforia® Create’s automated AI image analysis models.

Lallemand’s R&D lab in Tallinn, Estonia, the Competence Centre for Food and Fermentation Technologies, focuses on yeast derivative production process optimization and yeast-derived bioactive compound research. We spoke with Ildar Nisamedtinov, VP of Research & Development Coordination, to learn more about applying Aiforia’s AI models to support research and development on yeast fermentation contamination.

Tell us about your project with Aiforia

Ildar Nisamedtinov: "We aimed to use AI-powered image analysis technology for identification of contamination in yeast fermentations. As a manufacturer of yeast starter cultures we want to make sure that our products are clean of microbial contamination.

In most cases, the conventional methods for contamination detection rely on plating assays, which for some microorganisms may take several days until results are obtained. We do not want to replace these assays but use them in parallel with a rapid and robust analysis method, which would allow us to make decisions in production more proactively. An AI-based microscopy image analysis might be an efficient and quick quality test method for this purpose."

Why did you decide to use the Aiforia software?

"Aiforia is already actively selling its image analysis technology in the medical field (e.g., tumor cell detection), so we were sure it would also fit our requirements. Their proximity to our R&D lab in Tallinn, Estonia, was also a positive."

What did Aiforia allow you to do that you could not do with traditional tools?

"We expect to develop a robust and rapid detection method of microbial contamination in our products, which would allow us to minimize quality associated business risks. It is not ready yet, but we are working hard in collaboration with Aiforia to get there."

What is the biggest benefit of using AI in your work?

"Like many other companies, we at Lallemand are also embarking on the Industry 4.0 journey. The given project with Aiforia is one piece of our general goal to move towards full digitization of the entire yeast production process, including quality control. As a result, we expect to improve the production process efficiency and quality of our products."

Read more case studies:

References

Seung-Oh et al. (2020). Anti-Contamination Strategies for Yeast Fermentations. Microorganisms, 8(2), 274; https://doi.org/10.3390/microorganisms8020274